Vertical Mills | VMC | Haas CNC Machines | Haas Automation

A Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for .

WhatsApp)

WhatsApp)

A Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for .

The plain vertical machines are characterized by a spindle located vertically, parallel to the column face, and mounted in a sliding head that can be fed up and down by hand or power. Modern vertical milling machines are designed so the entire head can also swivel to permit working on angular surfaces,

Finest wet grinding technology – the laboratory mills of the MicroSeries are an investment in the future for new product developments of different fields of application of pigmented ink jets, technical ceramics, cosmetics, pharmaceutical applications and nanoscale hightech products.

Mill Machining, Milling Process, Horizontal Vertical Milling Machines Definition. Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large .

Motor power and media addition. The power drawn by the Vertimill motor is required to establish the grinding rate. Motor power should be measured using corrected power. As the grinding media wears fine enough to be carried out by the uprising velocity in the mill, the total media charge will diminish, and the power draw will decrease.

"stirred ball mill." There are quite a few types of Attritors; we can categorize them as dry grind Attritors, wet grind Attritors, regular speed Attritors, and high speed Attritors. A useful and simple equation describing the grinding momentum is M x V (mass x velocity), which enables us to see how the Attritor fits into the family of mills.

Vertical Dry Powered Mill Introduction Of Vertical Milling Machine. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. 250tph limestone crushing line in Kenya. 250tph granite crushing line in South Africa. 120tph granite crushing line in Zimbabwe.

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit. xConsistently high product quality with minimum energy requirement, due to the integrated highefficiency

Size Reduction Milling From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies. Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding, we can help. ... Alpine ATR Vertical Dry Media Mill.

Mining Technology | Mining News and Views Updated Daily is using cookies ... In July 2012, RWE Power in Essen commissioned a new vertical roller mill from Loesche. Read more. 10 October 2012. Loesche ThermoProzess Moves to New Location. ... The dry milling of ore in Loesche vertical roller mills has shown significant process advantages, as well ...

Baker 4 head bandsaw with return bought brand new in 1996 480 V needs a couple of wheels and missing some guide parts. running up until taken out of service 2 years ago. 20HP motors and air tensioning on the blades.

Apr 11, 2018· I''ve had a few goes at designing a power feed for my mill over the years but they have been abandoned through lack of suitable motor/ speed control. ... Rockwell Horizontal/Vertical Mill Rebuild ...

The sJet ® System (patent pending) is a new innovation in a line of consistent developments being made in the area of air jet milling. Final finenesses in the submicron range (example: d 50 µm) can now be achieved with fluidized bed jet mills. As opposed to conventional dry grinding processes with fluidized bed jet mills, the sJet ® System uses superheated steam as its milling .

Loesche roller grinding mills, ensuring their reliability and safety. Each of our drygrinding installations thus represents our technological prowess, offering advantages that ensure the competitiveness of our customers: • No metallic contact between grinding components (even when a coal mill is empty), thus avoiding the generation of sparks.

Risk Assessment Milling Machine (Horizontal and Vertical) 17 February 2016 3 of 4 Ref; Health Safety Executive Engineering in Workshops the whole of the foot, should be worn when using any machine. Open toed and light canvas shoes are not acceptable, anyone wearing these not be allowed into the

grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalent.

The VM series of 3axis machining centers features a small footprint with a large work cube. No other CNC mill packs as much productivity into such an efficiently designed package. ...

Apr 22, 2018· The stepper controlled power feed is very successful. Plenty of power available. I cannot stop the feed even if I screw the table lock fully in and speed is very controllable.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Used Vertical CNC Mill for sale (79) currently in stock Brand New Vertical CNC Mill for sale (22) currently in stock. View Machines Are the top of the line. CNC Mills or Machining Centers are Computer Numerical Controlled and can vastly speed production and set up time.

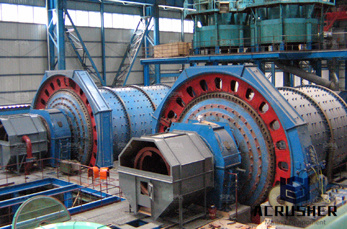

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill.

Historically mills were powered by hand or moisture from aggregate or soil and to produce "dry fills" prior to vertical mills, Grinding laws · Grinding machines vertical dry grinding mill principles DXN. Home > Trapezium Mill > Vertical Dry Grinding Mill Principles: How Do Water Mills Work, Corn Mill Machines, Water Powered Mills, Hammermill, St .

vertical dry powered mill . Vertical Mill | Summit Machine Tools For Metalworking vertical dry powered mill,Summit has vertical mills and machine tools for sale. Get a quote on a vertical mill today! Get a quote on a vertical mill today! In order to give you a better experience this website uses cookies.: Used Milling Machines / Power Tools ...

WhatsApp)

WhatsApp)