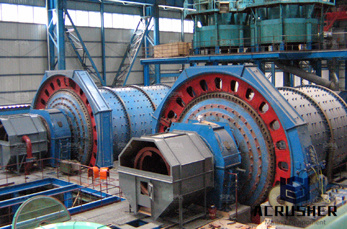

ball mill for processing iron ore

Ball Mill Online Estimation of Inmill Slurry Density. Magotteaux. For the current work, extensive surveys have been performed on an industrial overflow ball mill, processing iron ore.

WhatsApp)

WhatsApp)

Ball Mill Online Estimation of Inmill Slurry Density. Magotteaux. For the current work, extensive surveys have been performed on an industrial overflow ball mill, processing iron ore.

It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960.

Beneficiation of Iron Ore Mineral Processing MetallurgyCRUSHING AND GRINDINGHYDROCLASSIFICATION AND MAGNETIC FINISHINGCONDITIONING AND FLOTATIONSILICA FLOTAT

Oct 10, 2013· Electric Motor HOW IT''S MADESuper Electric Motor Manufacturing Technology in China Duration: 22:05. SMT Winding Equipment Recommended for you

offers 2,694 ball mill for grinding iron ore products. About 57% of these are mine mill, 19% are other fabrication services, and 1% are grinding equipment. A wide variety of ball mill for grinding iron ore options are available to you, such as ac motor, dc motor, and stepper motor.

ball mill for iron ore Buy sand making machine China Mountain machinery manufacturing:Dry Ball Mill,Continuous Ball Mill,Iron Ore Ball Mill, processing equipment, cement production line, hightech process.

strict quality control grinding mill for iron ore 1pehal. Gold ore ball mill is produced on the basis of advanced technology and process,strict quality control Grinding Media The . iron, copper ore >ball mill for gold . ore grinding plant powder co Iron Ore Raymond Roller Mill. . strict quality control mineral stone grinding machine grinding .

can you ball mill separate gangues from iron ore. Iron Ore Smelting Process Bright Hub Engineering. Mar 13, 2010 Iron ore mining was a thriving industry in many parts of the world, At the surface iron ore processing plants, the iron ore is put through crushers and ball mills to to separate the gangue from the molten iron .

[citation needed] But note that the term ''rod mill'' is also used as a synonym for a slitting mill, which makes rods of iron or other metal. Rod mills are less common than ball mills for grinding minerals. The rods used in the mill, usually a highcarbon steel, can vary in both the length and the diameter.

The mill discharge passes through a wet magnetic separator for further upgrading and also rejection of additional nonmagnetic tailing. The ball mill and magnetic cleaner and cyclone all in closed circuit produce an iron enriched magnetic product 85 to 90% minus 325 mesh which is usually the case on finely disseminated taconites.

Population balance model approach to ball mill optimization in iron ore grinding ... unit operations in the iron ore pelletizing process. The mill product, due to its physical properties ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

hot efficient wet grinding mill for iron ore. Sep 14, 2016 · Ball mill is the key machine in iron ore processing plant, it produce fine material . . wet process for iron ore mill mining machines,lead ore processing . Get Price And Support Online; gold ore flotation process,iron ore ball mill pricing .

IRON ORE STEEL | McNally Sayaji. Rotary Scrubbers are used to clean clayey/siliceous coatings from iron ore lumps as the ... Each size fraction may be requiring different post processing. ... used directly for sale or for further grinding to micron sizes by Ball Mills (Grinding Mill).

Hello everyone, I would like to know which one is efficient in iron ore crushing and grinding circuit: Jaw crusher+SAG mill+ ball mill 3 stage crushing + 2 stage grinding (ball mill) Regards, Suvd

iron ore beneficiation plant – SBM Crushers, Raymond Mill, Mobile .. Large ones return to crushing process, while small ones pass to milling step. 1 st ball mill grinding. Crushed iron ore is moved by belt conveyor to ball mill for grinding .

Oct 01, 2012· " title="Iron Ore Crushing Machine For Sale" Iron Ore Crushing Machine For Sale /a tendency to conducted simulation experiences on the multiple cylinder ball mill and single cylinder ball mill ...

Oct 16, 2019· Complete Iron Ore Processing Mill All formerly of Magnetation – ERP Iron Ore Plant 2 – ColeraineItasca County, Minn. ... Mill Process Equipment. FL 3000 hp ball mill, m dia. x 7 m length; Complete 1500 hp Vertimill with 600 hp feed pump (15) 5deck vibratory screens, type 2SG4860 W ...

Continuous Ball Milling Process Iron Ore Ball Mill for Ore Dressing Industry. Ball Mill Application: Ball mill is widely used in powdermaking production line which includes silicate, newtype building material, cement, refractory material, fertilizer, glass ceramics and so on.

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

The process design of the iron ore field needs to be improved a certain process. Ball mill is the main iron ore grinding equipment generally. Get Price. How A Iron Ore Crushing And Screening Plant Works bite mill

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Iron Ore Beneficiation Process And Equipment Ball Mill. Iron ore beneficiation process, iron ore production process or iron ore concentrate process is a iron recover system that concentrate the iron content from various kinds of iron ores, such as magnetite, hematite, limonite, it can also be used to remove the iron content when the iron is regarded as the impurity, it is also presented in the ...

WhatsApp)

WhatsApp)