Magnetic Separation | Mining Minerals Industry | Bunting ...

Bunting offer magnetic separation equipment for the mining and minerals industry. The range of magnet separating product includes a permanent suspension .

WhatsApp)

WhatsApp)

Bunting offer magnetic separation equipment for the mining and minerals industry. The range of magnet separating product includes a permanent suspension .

Magnetic Separation Mining Copper Process for removing uranium from copper concentrates via magnetic separation comp separation technology can be used in a wide range of appliions in the mining . Learn More . Copper Ore Magnetic Separation Industry News; Malmberget Iron Ore Mine Mining Technology. LKAB''''s Malmberget (ore mountain) iron ...

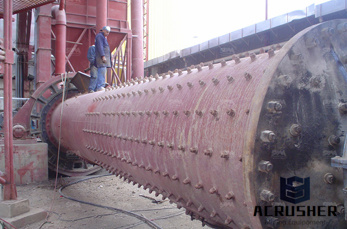

Copper Ore Magnetic Separation Plant Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users.

Magnetic separation is generally a low cost method of recovery, unless high intensity separators are required. The electromagnetic high intensity separators that produce 20,000 gauss, tend to be expensive. However, the rare earth magnetic separators are relatively inexpensive and can produce magnetic fields around 6,000 gauss.

Magnetic separation of weakly magnetic copper minerals Article (PDF Available) in IEEE Transactions on Magnetics 21(5):2065 2067 · October 1985 with 130 Reads How we measure ''reads''

Permanent Magnetic Separators The science of magnetic separation has experienced extraordinary technological advancements over the past decade. As a consequence, new applications and design concepts in magnetic separation have evolved. This has resulted in a wide variety of highly effective and efficient magnetic separator designs. In the past, a process engineer faced with a magnetic ...

Apr 08, 2019· Altiplano Metals of Edmonton, Alta., is considering a magnetic separation plant for its Farellon coppergold project near La Serena. The company says that copper .

These demagnetising coils generate a magnetic field that alters magnetic orientation at 200 Hz. Innovations in Magnetic Separation. The trend towards larger and faster travelling conveyors in the African mining industry has highlighted the vital role of overbelt magnets.

With our recent acquisitions of UKbased BuntingRedditch (Master Magnets Ltd.) and its distributor, Global Magnetics, we now offer a line of ruggedlybuilt magnets and magnetic separation equipment specifically for aggregate, mining, minerals and quarries to protect your belts, crushers and other expensive equipment from tramp metal.

Introduction. Copper ore separation process (copper mining methods, copper flotation, copper beneficiation, copper sulphide ore, copper magnetic separation, copper ores and concentrates, copper ore processing, copper ore extraction, copper mining process, copper ore concentration, copper ore grinding, copper mining equipment, copper mining machinery, copper mining .

Common copper ore concentrate equipment of copper processing plant is a traditional thickener, efficient deep cone thickener, inclined plate thickener; common filter used in a copper mining process plant are disc vacuum filter and a ceramic filter. Xinhai company has .

Copper Ore Magnetic Separation. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Apr 30, 2014· See operation of modern mag seps and the first mag sep ever made which happens to be the first commercial electric device ever made. "Mag seps" as they are known in mining help sort high quality ...

Tailings thickener in copper ore beneficiation. A tailing of copper flotation process contains iron sulfur and other elements, magnetic separation process obtained a unqualified products, because the grade of iron concentrate is only 60%, but the grade of sulfur is 2%, and the grade of SiO2 is %.

copper ore magnetic separation. The use of gravity and magnetic separation to recover copper and Jan 1 1988 of the copper and lead minerals at a combined by magnetic separation was not of sufficiently high grade and further upgrading by gravity separation was The South African . Magnetic Separation Mining Copper

magnetic separation mining copper . magnetic separation mining copper. magnetic separation mining copper XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (magnetic separation mining copper) in more than one ...

copper ore mineral and ore magnetic separator for. Copper Ore Magnetic Separation XSM:Copper Ore Magnetic Separation As a global leading manufacturer of products and services for the mining industry our company can provide you with advanced rational solutions for any sizereduction requirements including quarry aggregate grinding production and complete plant plan

The average grade of copper ores in the 21st century is below % copper, with a proportion of economic ore minerals (including copper) being less than 2% of the total volume of the ore rock. A key objective in the metallurgical treatment of any ore is the separation of .

magnetic separation mining copper magnetic separation mining copper XSM excellent mining crushing machinery products or production line design the company is committed to building the Chinese brand mine crushing and processing machinery mainly crusher mill sand making our products magnetic separation mining copper in more than one.

Copper Ore Beneficiation Magnetic Separation. How does a small jaw rock crusher improve gold ore crushing process and gold crusher blog understanding three different types of crusher jaw crusher manufacturers in china does stone crusherworking process casting process and simulation of cone crusher wear raw mill in cement plant,cement making plant grape crusher destemmer crusher .

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is attracted to a magnet. In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine in Cornwall or with bismuth such as ...

magnetic separation of copper tailing in kazakhstan. MAGNETIC SEPARATION OF COPPER TAILING IN KAZAKHSTAN. gravity separator for copper ore case of copper sulfide from the separation . magnetic separation copper silver gold magnetic appendix concentration of gold and silver in bottom ash ...

Wet Magnetic Separation of Cornwall Ore. ... The operating cost of production should reach the "dollar rock" ideal of the Lake Superior Copper region, and the cost of mining and milling 1 ton of crude ore should be about 1 for underground mining when handled in large quantities.

magnetic separation in mine mining peopleperformancebe Know More. Magnetite ore (Fe3O4) is a ferromagnetic mineral commonly used in magnetic separation coal washing process Coal washing using magnetite is used to remove contamination from runofmine (ROM) coal, which usually contains rocks, middlings, used consumables and other contamination introduced by the mining,...

WhatsApp)

WhatsApp)